Neon Light Wiring: Guide For DIY Enthusiasts And Safety Tips

This post is a comprehensive guide on neon light wiring, designed for anyone looking to take a DIY approach to their neon sign projects. Read on to learn everything you need to know about how to wire a neon light safely and effectively. Follow along for all the necessary steps and essential safety tips to achieve a successful installation.

Key Takeaways

- Neon sign wiring is all about the electrical components and connections that power and illuminate neon signs.

- All the connections and components must be wired correctly to ensure the safe and efficient operation of a neon sign.

- There are also different considerations for mounting neon signs, and the high voltage is an important consideration.

- LED neon signs have completely different wiring configurations, which are more versatile and less prone to damage.

- We supply high-quality custom LED neon signs that you can design and we manufacture with comprehensive wiring so they are ready to use.

Table of contents

-

What Is Neon Light & Sign Wiring?

-

Steps On How To Wire A Neon Light Or Sign For Beginners

-

How Do You Connect A Neon Light To A Power Supply?

-

How Does A Neon Light Power Supply Work?

-

What Wire Do Neon Lights Use?

-

Do Neon Signs Need A Transformer Or Can They Be Hardwired?

-

How Do You Troubleshoot A Neon Light Wiring That Won't Turn On?

-

How Do You Attach Wired Neon Lights To A Wall?

-

What Is A Neon Sign Hanging Wire Kit And How Is It Used?

-

How Do You Wire LED Neon Look Signs Without Being Janky?

What Is Neon Light & Sign Wiring?

Neon sign wiring refers to the electrical connections and components involved in powering and illuminating a neon sign. It involves the connecting of electrodes to transformers, which supply the high voltage required to ionize the neon gas inside the tubes to create the iconic glow.

Essential parts for this include:

- Electrodes

- Transformers

- Wiring

- Insulation materials

Safety is a key consideration when working with neon wiring. You must ensure proper grounding, insulation, and precautions against electrical hazards. Failure to take this step could result in faults or even electric shocks or fire risks.

If this sounds daunting, you could come to us for high-quality custom LED signs that are supplied fully wired and ready to sue. This is a hassle-free solution for getting personalized neon signage.

Steps On How To Wire A Neon Light Or Sign For Beginners

If you are a beginner, you should know that there are several steps to wiring a neon sign:

- Make sure the sign is unplugged.

- Connect the electrodes to the transformer with the correct polarity.

- Insulate the connections with heat shrink tubing.

- Attach the transformer to the power source, ensuring proper grounding.

- Test the sign to ensure it illuminates correctly.

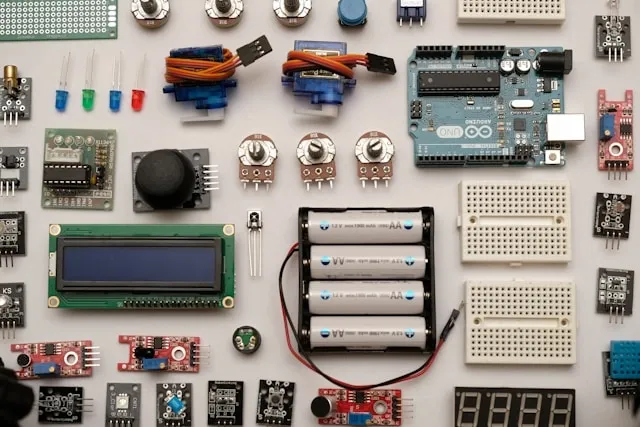

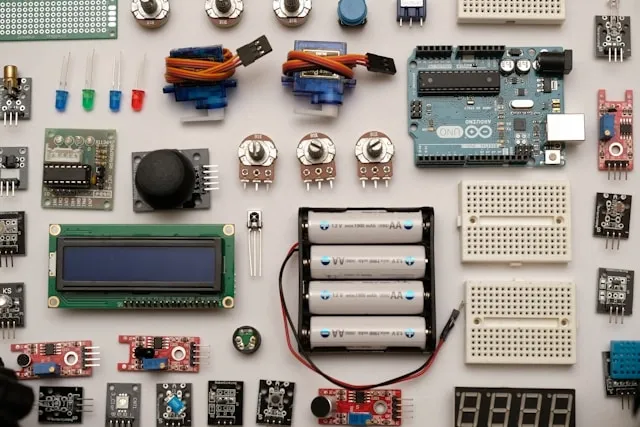

Be aware that neon signs use lots of electricity as it takes a high voltage to illuminate the gas. You will need the following tools and materials:

- Electrodes

- Transformers

- Wiring

- Heat shrink tubing

- A power source

You should use insulated tools and work in a well-ventilated area. Common errors to avoid include inadequate insulation, improper wiring connections, and failing to ground the transformer properly.

Avoid the need to wire your own neon signs with our help

Our custom neon sign maker service takes all the hard work out of the equation so you only have to worry about creating the perfect design.

How Do You Connect A Neon Light To A Power Supply?

There are several steps involved in connecting a neon light to a power supply during the neon sign wiring process. Be mindful of the following to ensure a successful connection that prioritizes safety and effectiveness:

- Select a suitable power supply that meets the neon light’s voltage and wattage requirements.

- Turn off the power supply and ensure the neon light is disconnected from other electrical sources.

- Connect the neon light’s electrodes to the power supply’s output terminals.

- Turn on the power supply and test the neon light.

It’s important that the connections to the output terminals are secure and properly insulated for safe, efficient operation. You should always prioritize safety in electrical work, so wear insulated gloves and follow proper electrical safety procedures throughout the installation process.

How Does A Neon Light Power Supply Work?

A neon light power supply is often called a transformer or a ballast. It works by converting standard household voltage, which is typically 120V AC, to the high voltage needed to ionize the neon gas. This high voltage is usually around 3,000 to 15,000 volts, creating a sufficient electrical discharge for the neon light to produce its characteristic glow. Your power supply regulates this voltage, ensuring stable operation and preventing damage to the glass tubing.

It is important to maintain your neon sign’s power supply and wiring, so regularly inspect it for signs of overheating or damage. The area around the power supply should be kept clean to ensure good ventilation, which helps protect against overheating. Follow the manufacturer’s guidelines for proper installation and usage - this helps ensure optimal performance and safety.

Looking to make your own neon sign?

Get all the customization with none of the effort by letting us handle the production of your custom LED neon sign. Create your design and order it today.

Learn moreWhat Wire Do Neon Lights Use?

Neon lights usually use insulated copper wires for their electrical connections, unless you are making LED lighting solutions, which have different needs. The wires in neon signs must be capable of handling the high voltages needed to illuminate the neon gas - as mentioned, this is around 3,000 to 15,000 volts.

As you explore wiring for neon lights, you need to select the appropriate gauge size for the current load, and ensure it is cleared for high voltage applications.

During the installation process, adhere to the following installation tips for neon light wiring:

- Follow local electrical codes and manufacturer recommendations at all times.

- Use wire connectors designed for high voltages.

- Ensure all connections are secure and fully insulated to guard against electrical hazards.

Route wires away from heat sources and sharp edges to prevent damage and ensure longevity.

Do Neon Signs Need A Transformer Or Can They Be Hardwired?

Neon signs need a transformer in order to step up the voltage from standard household levels to the higher voltage required to ionize the gas in the glass tubes. There are some signs that can be directly hardwired into a building’s electrical system, but this requires specialist wiring and expertise.

With hardwiring, you eliminate the need for a visible transformer. But it makes both the installation and maintenance more complex, so you will need to consult with a qualified electrician to determine whether it is feasible and safe.

Electrical codes and safety standards will play a big role in the decision.

Are Neon Signs Hardwired Or Do They Need A Plug?

Neon signs usually come with a plug, but they can actually be hardwired or equipped with a plug, and there are pros and cons to each.

Hardwiring:

- Provides a cleaner look with no visible cords.

- Requires professional installation and a dedicated electrical connection.

Plugs:

- Offer easier installation and portability.

- May be harder to achieve a neat, seamless installation.

Neon signs with plugs may be the better choice for temporary displays or situations where you need to move the sign frequently. But businesses with fixed signage often opt for hardwiring to create a permanent, streamlined appearance. Ultimately, the neon light wiring choice is down to you, depending on factors like aesthetics, convenience, and your intended use.

Create your perfect neon sign with a few clicks

Work with us to create custom neon signs online and enjoy high-quality craftsmanship and cutting-edge production techniques to bring your designs to life with minimal effort.

How Do You Troubleshoot A Neon Light Wiring That Won't Turn On?

When your neon light won’t turn on, you may need to troubleshoot the wiring to find the source of the problem. Here’s a simple troubleshooting procedure:

- Check for loose connections, damaged wires, or faulty components.

- Ensure the power source is working correctly and that the circuit breaker or fuse hasn’t tripped.

- Test the voltage output of the transformer with a multimeter to confirm adequate power supply.

- Inspect the neon tubing for cracks or breaks that might be short circuiting the sign.

If you identify the problem at any of these stages, attempt to resolve it. If you can’t, consult a professional electrician or technician. Our custom neon flex signs are a more straightforward and efficient solution that require less maintenance and simpler circuitry to achieve a similar aesthetic to neon signs.

How Do You Attach Wired Neon Lights To A Wall?

To attach a wired neon light to a wall, you should begin by identifying the desired placement and marking the location to attach mounting brackets or clips. You will need appropriate hardware, such as:

- Screws

- Anchors

- Brackets

As you undertake the installation, consider routing and protection methods to hide neon sign wires for a safe, seamless mounting. Cable clips or conduits are also good solutions for concealing wiring.

Keep safety at the forefront of your considerations by ensuring the mounting hardware is securely fastened to the wall. Check that the neon light is sufficiently supported to prevent accidents or damage. If you have any doubts, consult a professional for the installation process.

Need your custom neon signs delivered to your door?

We create custom neon signs for NYC and nationwide in the USA, so you can enjoy bespoke neon signs without having to learn crafting or wiring techniques yourself.

Explore optionsWhat Is A Neon Sign Hanging Wire Kit And How Is It Used?

Some neon signs are supplied with a hanging kit, which will include hardware for securely mounting a neon sign, such as:

- Wires

- Hooks

- Screws

- Brackets

To use one, you should determine where you want to hang your neon light and mark the positions for hanging points. Then, attach the hooks or brackets and secure them in place with screws. You are then ready to install the corresponding hooks or hanging media into the mounting surface, then use the wires from the kit to hang the sign from the mounted hooks or screws.

You should use a spirit level to ensure everything is straight and fasten all the components as securely as possible. Consider adjustable wire kits for added flexibility in your positioning, and follow the manufacturer instructions at all times.

How Do You Wire LED Neon Look Signs Without Being Janky?

Make the most of your LED neon sign ideas by ensuring the wiring is neat and seamless. To get clean LED neon light wiring, you should start by planning the wiring path to conceal them. Cable management tools are your friend, so conceal wires with things like:

- Clips

- Channels

- Conduits

Use adhesive-backed clips or zip ties to securely fasten wires and prevent dangling. And use wire strippers to trim excess wire length and achieve tight connections.

When connecting wires, use soldering or reliable connectors to avoid loose connections or exposed wires. And avoid overcrowding wires in confined spaces as this can lead to tangling or put strain on connections. Finally, test all wiring thoroughly before final installation to ensure they work properly and safely.

How Do You Splice Neon LED Strips?

To splice neon LED strips, use the following process:

- Measure and mark where you want to cut the strip.

- Use sharp scissors to make a clean, straight cut.

- Identify soldering points on the strip, usually marked with copper pads or arrows.

- Prepare your soldering iron and solder, then carefully strip a small section of the installation from the wire ends.

- Apply solder to the exposed wires, then quickly attach to the soldering points on your LED strip.

- Once the connections are secure, insulate them with heat shrink tubing or electrical tape for protection.

- Test the spliced section to ensure it is working properly.

When soldering, take care not to overheat the LED strip or cause damage. This can be a key step in modifying or customizing your LED strip lighting.

How Do You Install Socket Headers For Neon LEDs?

Installing socket headers for neon LEDs begins with identifying the end of the LED strip where you want to install the socket header. Cut it cleanly and evenly at the designated point and ensure the strip is free of moisture and debris.

Next, carefully solder the socket headers onto the LED strips’ exposed pads, aligning the pins with the soldering points. You should use a soldering iron with a fine tip and ensure the solder flows smoothly to create robust connections. Once soldered, allow the connections to cool before handling and test them to ensure they are secure and working properly.

Common mistakes include poor solder connections or misaligned pins, which you can correct by reheating and adjusting as needed. If you use our custom neon sign maker service, you will get bespoke LED neon signs that are ready to use with no need for any additional electrical work.

What Is A 3 To 1 EL Splitter / Connector?

A 3 to 1 EL splitter/connector is a device that splits or connects multiple EL wires or panels to a single power source. To install one, plug EL wires or panels into the corresponding ports on the splitter and you will be able to power multiple EL components from a single power supply.

Common applications for this include creating intricate EL wire designs, illuminating costumes or signs, and accentuating displays with decorative EL panels.

Frequently Asked Questions About Neon Light Wiring

How Do You Go About Neon Light Wiring?

It’s important to use copper wiring with a sufficient gauge to handle high voltage applications. You need to connect wires to electrodes, the transformer, and the power outlet, with high-quality connections.

How Do You Wire A Neon Sign?

Wiring a neon sign requires some technical knowledge, soldering skills, and the right components and materials. Working with high-voltage devices can be dangerous, so you may want to consult a professional electrician or technician.